Description

Use and application

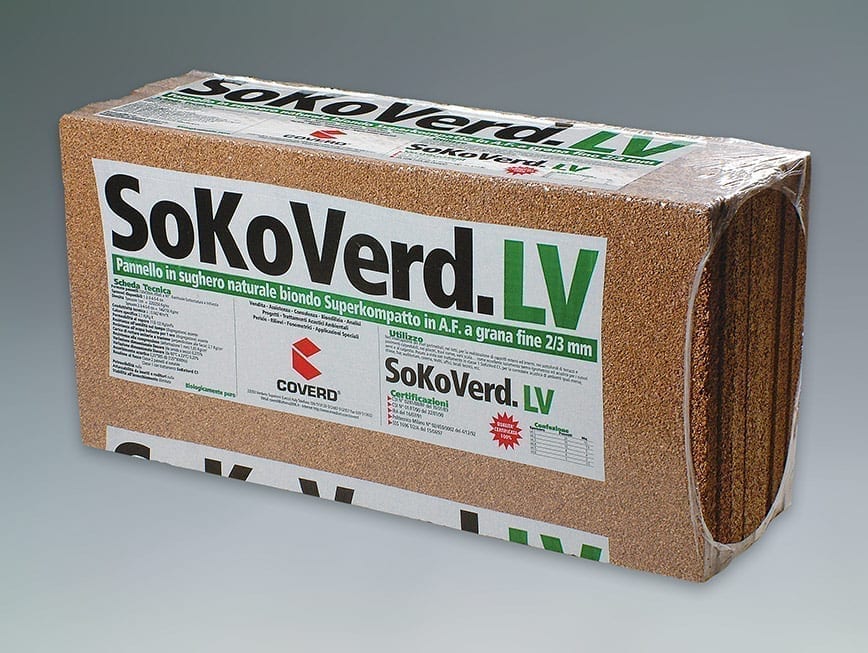

Due to its excellent features, it is particularly suitable for eco-friendly buildings with reduced environmental impact and low energy consumption. The most appreciated features are: low thermal conductivity, high transpiration, high mass, high elasticity, very low thermal diffusion, high humidity resistance. KoFlex cork panels have a wide range of applications, such as:

- Improvement of acoustic and anti-condensation insulation in false ceilings in dry systems

- Improvement of acoustic and anti-condensation insulation in walls and counter walls in dry systems

- As anti-vibration, to lay under and over, indoor and outdoor walls

- As anti-noise, to dry lay between floor foundation and screed

- As anti-noise, to dry lay between screed and floating floors (laminate or parquet)

- As anti-noise, to lay with glue between screed and ceramic floors or parquet

- As acoustic and anti-condensation insulation, to lay with glue on cold walls or cold ceilings

Item specification

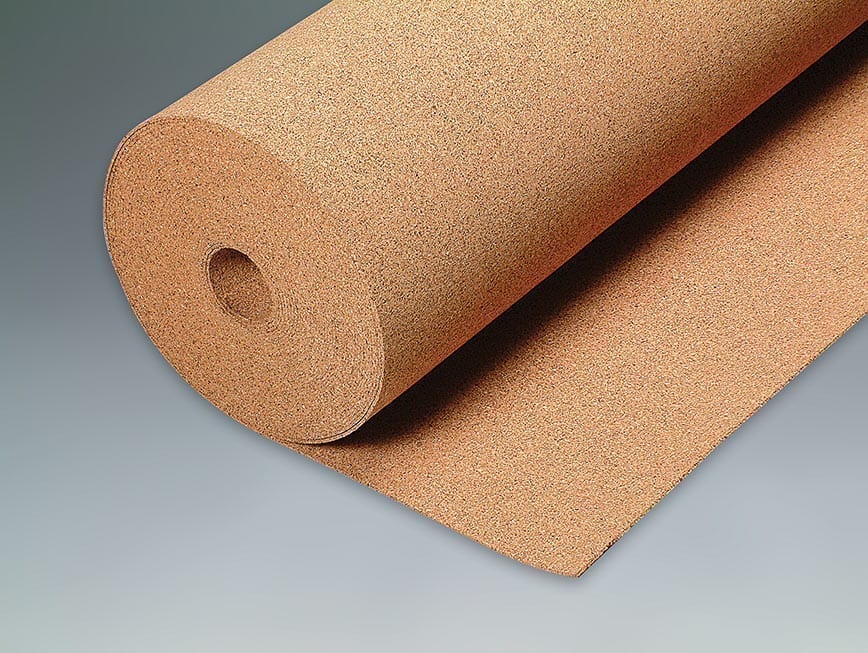

… Insulating layer composed of super-compressed light natural cork panels (KoFlex), very flexible with high specific weight and polished on both faces, thickness of … mm of selected quality …

Bio-compatibility

The KoFlex panel, has no negative effects on the healthiness and transpiration of inside spaces because it is totally composed of natural cork. By its nature, it doesn’t cause allergies and doesn’t produce irritating dust during the processing and application step. The panel KoFlex is comparable, for its nature, to a wooden element.

Eco-compatibility

KoFlex panels, are obtained by grinding cork barks. The barks picking doesn’t require tree felling. Barks grow back naturally, without chemical fertilizers and a new picking is possible after only ten years. Therefore the cork is a renewable and inexhaustible resource. The picking process is manually done, with just a minimum use of machinery. Production and transport require a low energy consumption because of the lightness of the product. Production wastes (dust, etc.) are burned to produce thermal energy, used for the same production or in agriculture. Processing wastes are completely reusable.